AURORA project manage able to achieve whole procedure from project beginning to perfect completion. Project manage is the blood of company life, it is controlling during all the mould design, tooling manufacture, injection molding process. Every project is charged separately by one Project manager which is also in charge of all business and technical communication for this project with customer.

Time and Quality is uppermost important point in the project manage.

Time: AURORA make schedule for all the process since from project beginning. Every stage delay are will point out in week meeting and adjust people and work way to get mold test and mold complete on time. We provide weekly report on every Friday.

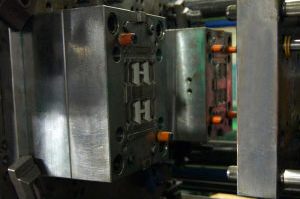

Quality: Aurora pay most attention to quality for project in every process. We has full experience people checked mold design before work. And we are checking the dim for all the Drilling,CNC,Wire Cut,Electrodes,EDM etc process and molding parts. All the quality problem will found in advance of mold test.